Ultrasonic gun cleaners are becoming a popular option for owners of firearms. Any items placed inside an ultrasonic cleaner are cleaned using ultrasound technology, water, or a cleaning agent. Ultrasonic cleaners only take a few minutes to clean an item. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Gun Cleaner Manufacturers

Ultrasonic Gun Cleaning Process

During ultrasonic cleaning, high-frequency waves stir the liquid to produce cavitation bubbles. Generator-powered transducers are attached to the tank's bottom and shake the solution. Cavitation bubbles implode upon contact with parts in the solution and subsequently clean incredibly hard-to-reach locations.

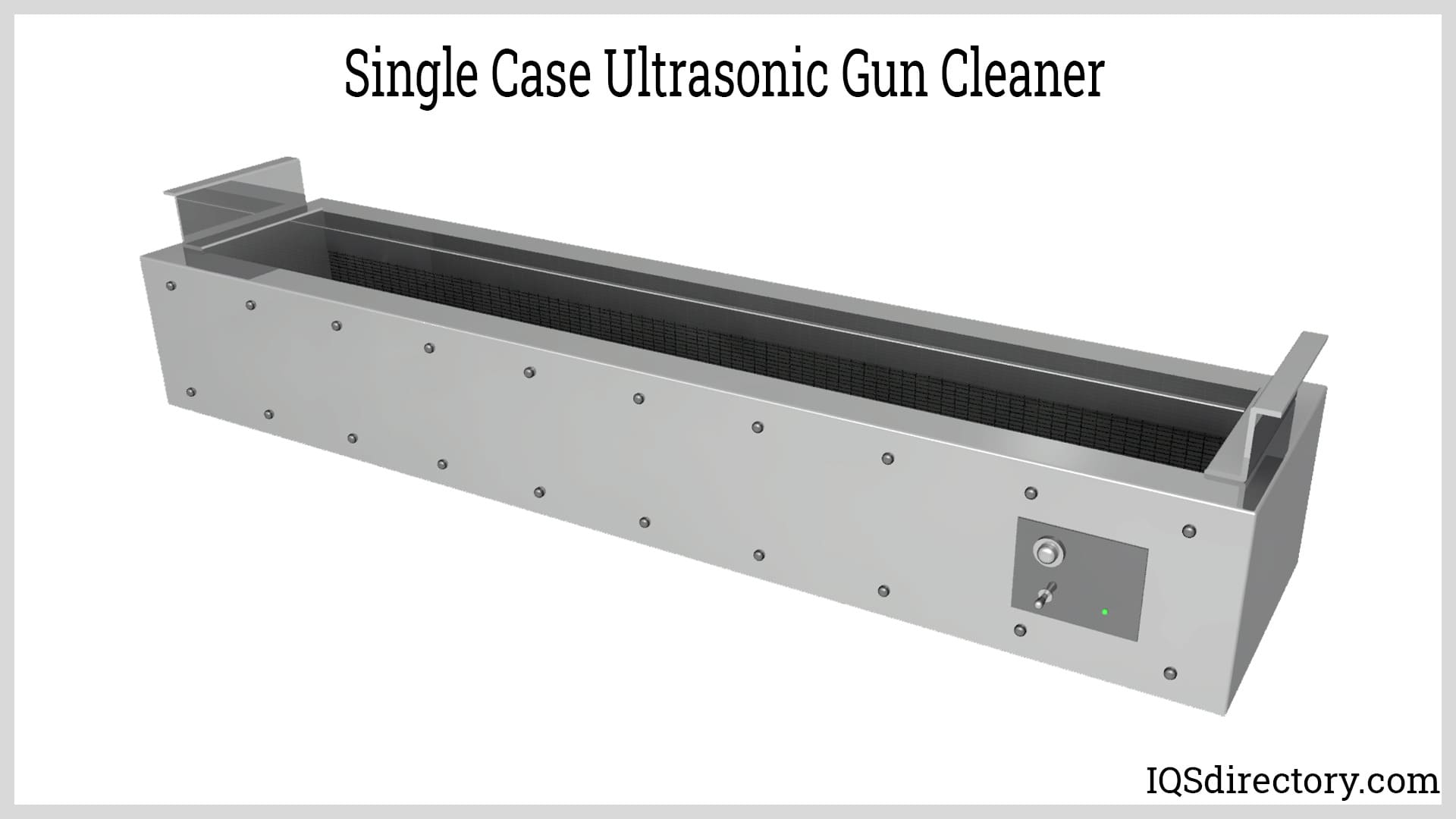

This is an effective decontamination process because the liquid infiltrates the smallest places that conventional cleaning techniques would miss. Typically, an ultrasonic cleaner consists of a sizable steel tank that houses a cleaning agent. The cleaner can be switched on and off externally. Ultrasonic gun cleaners come in various sizes, designed to handle one or multiple firearms.

What to Consider When Using Ultrasonic Gun Cleaners

Small ultrasonic gun cleaners for home use are widely available in hunting stores, along with the proper cleaning agent. In addition to hunters and hobby gun owners, police enforcement organizations use ultrasonic gun cleaners. Cleaning firearms regularly and thoroughly will prevent jamming or malfunctions while using them. An ultrasonic gun cleaner cleans firearms up to 3 times faster than conventional methods and prevents rust from forming in the gun.

The procedure for lubricating an ultrasonic gun is also a step in the cleaning process. Another product in simple ultrasonic gun cleaners is an ultrasonic lubricant, which forces lubricant into every nook and cranny of the firearm. It is an essential component of ultrasonic gun cleaning to ensure effective ultrasonic care and lubrication of a gun part.

How Ultrasonic Gun Cleaners Work

A gun requires regular cleaning to preserve accuracy, safety, and lifespan. Armed with only rods, brushes, pads, solvents, and oils, manually cleaning and lubricating firearms can be time-consuming and ineffective. The typical gun owner cleans, lubricates, and oils the surface of their weapon before spraying lubricant inside, hoping it will reach all vital internal parts. This gives the pistol a beautiful look. But it may be problematic because they are packed with carbon, filth, lead, and gum.

Ultrasonic Gun Cleaning Stage

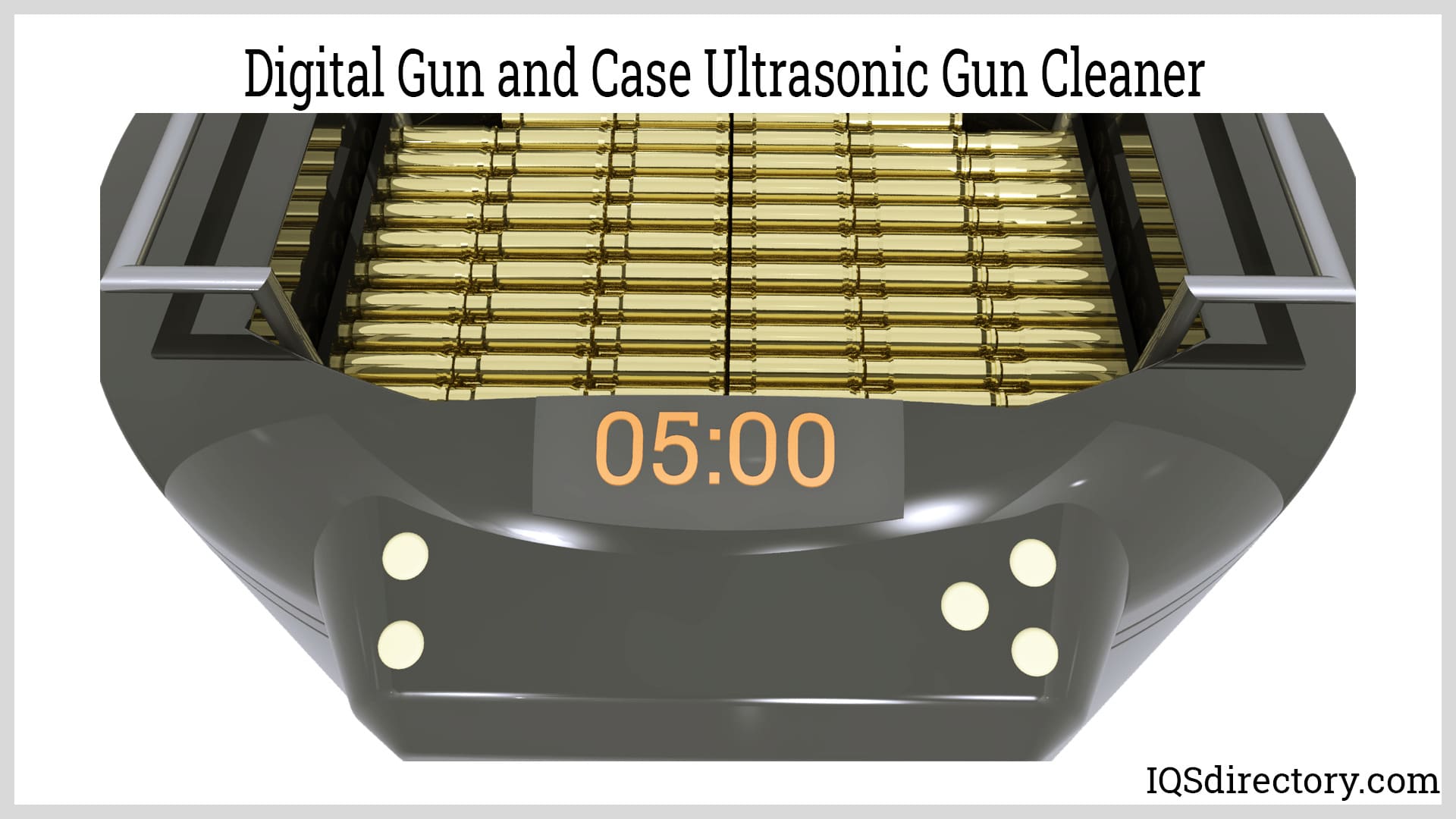

One only needs to load items into a basket and turn on the machine, and the ultrasonic and the right chemistry will take care of the rest. Ultrasonic cleaning devices use sound waves to create small bubbles that penetrate and extract soil from hard-to-reach places. The small bubbles remove the dirt from the weapon's surface, imploding and releasing energy bursts. One places the gun parts in the solution, turns on the switch, and watches the gun pieces spew out a dark cloud of filth.

Rinsing stage

All the cleaner and remaining pieces of loose debris can be eliminated with a brief ultrasonic rinse. In addition, using ultrasonics during the rinsing process helps prevent the transfer of any cleaning solution into the oil stage, which could damage a gun.

Lubrication Stage

Using ultrasonic technology, oil is injected deeply into all of the gun's crevices. Instead of rubbing oil on the gun and hoping it gets into every crevice, one may submerge the basket of components in a tank of oil, where the cavitation and agitation caused by the sound waves force oil into every nook and cranny. Hand lubrication of guns can take a long time and result in severe damage if done incorrectly. The lubricating process is essential to keep a gun free of corrosion and prevent rust. Every area is appropriately lubricated thanks to ultrasonic technology.

Choosing the Right Ultrasonic Gun Cleaner Manufacturer

To make sure you have the most beneficial outcome when purchasing ultrasonic gun cleaners from an ultrasonic gun cleaner manufacturer, it is important to compare at least 4 to 5 manufacturers using our ultrasonic gun cleaner directory. Each ultrasonic gun cleaner manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ultrasonic gun cleaner company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple ultrasonic gun cleaner companies with the same message.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services