An ultrasonic cleaning machine transforms electrical energy into ultrasonic energy, creating sound waves typically 20 KHz to 200 KHz above the human hearing range. These waves produce cavitation bubbles, which quickly implode and act as strong tiny vacuums. As they burst, substance and energy are released internally. Materials in the ultrasonic cleaning tank are cleaned when the bubbles in the tank collapse and suck away debris. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Cleaning Machine Manufacturers

Metals, lenses, jewelry, dental equipment, watches, fasteners, and other items can be cleaned with ultrasonic technology. This technology is employed to clean parts of filth, oil, grease, and other impurities.

No matter what cleaning agent is employed, experts advise making sure it is identified as an ultrasonic cleaning agent on the label. While it may be tempting to save money by using dish detergent or an all-purpose cleaner in an ultrasonic cleaner, particular cleaning solutions are needed for when ultrasonic energy is injected into a liquid for the device to perform successfully. A solution must have a particular viscosity and density for effective high-frequency sound wave formation during ultrasonic cleaning.

Building an Ultrasonic Cleaning Device

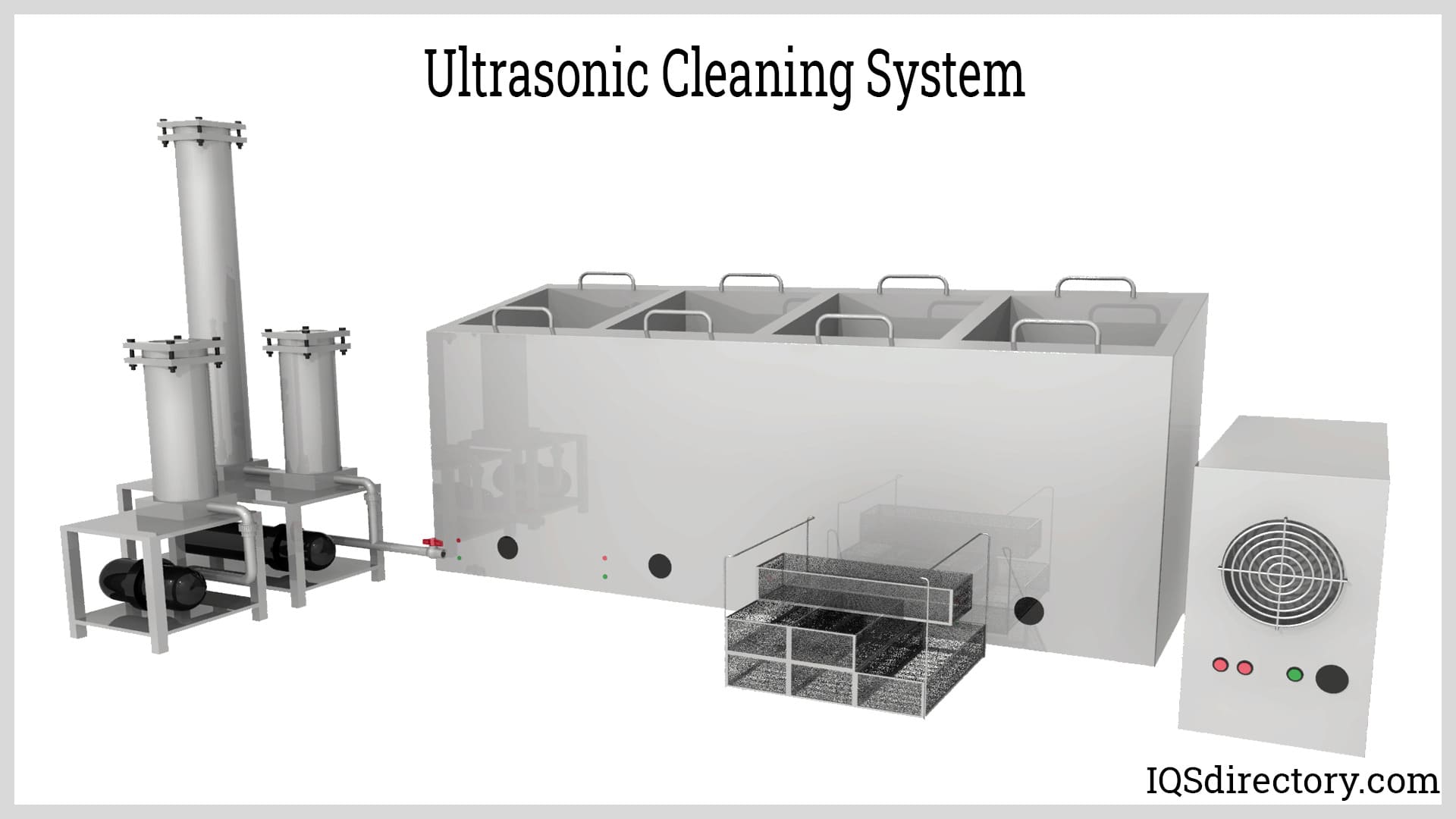

The following fundamental parts make up an ultrasonic cleaning device, also known as an ultrasonic bath device or ultrasonic washer:

- Ultrasonic Cleaning Tanks

- Ultrasonic Generators

- Ultrasonic Transducers

These machines also control cleaning duration, sweep, pulse, degassing, temperature, ultrasonic frequency, ultrasonic power, auto safety shutoffs, and other nuances, ranging from basic on/off switches to sophisticated microprocessors.

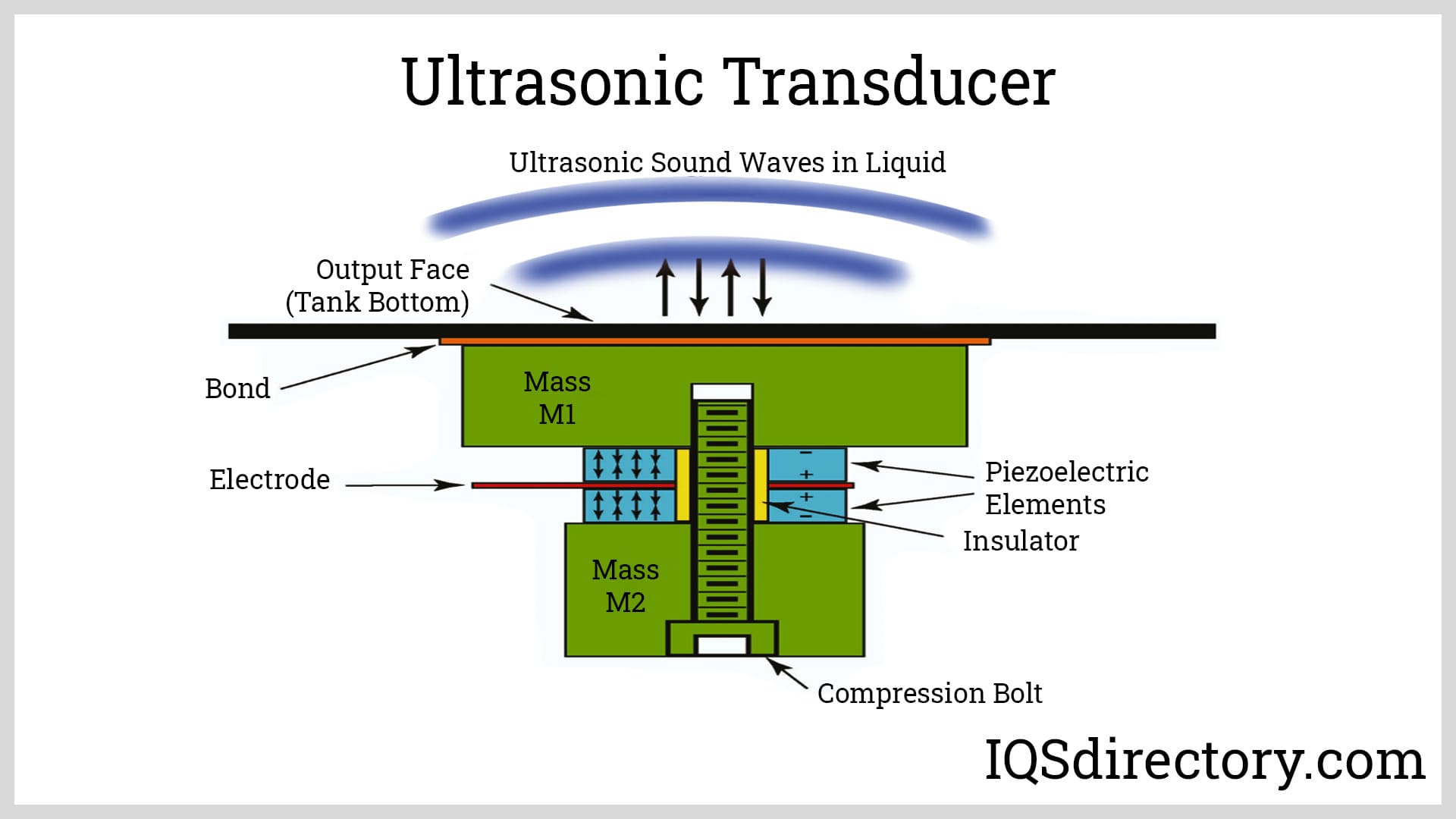

Ultrasonic Transducers

The essential element of an ultrasonic cleaning device is the ultrasonic transducer. This is an instrument that produces sound above the range of human hearing. It is bonded to the tank's bottom and produces cavitation; the transducer transforms the electrical signal from the ultrasonic into mechanical energy.

The ultrasonic transducer consists of the radiating element, the backing plate, and the active element. A piezoelectric crystal is an active component in most ultrasonic cleaners. The piezoelectric effect occurs when crystals receive electrical energy and change size and shape. The piezoelectric crystal transforms electrical energy into ultrasonic energy. The ultrasonic transducer's thick backing absorbs the energy that the piezoelectric crystal's back radiates.

An ultrasonic transducer's radiating plate functions as a diaphragm to transform ultrasonic energy into mechanical waves in the fluid. As a result, the radiating plate produces ultrasonic vibrations in the cleaning solution in response to electrical energy pulses received by the piezoelectric crystal.

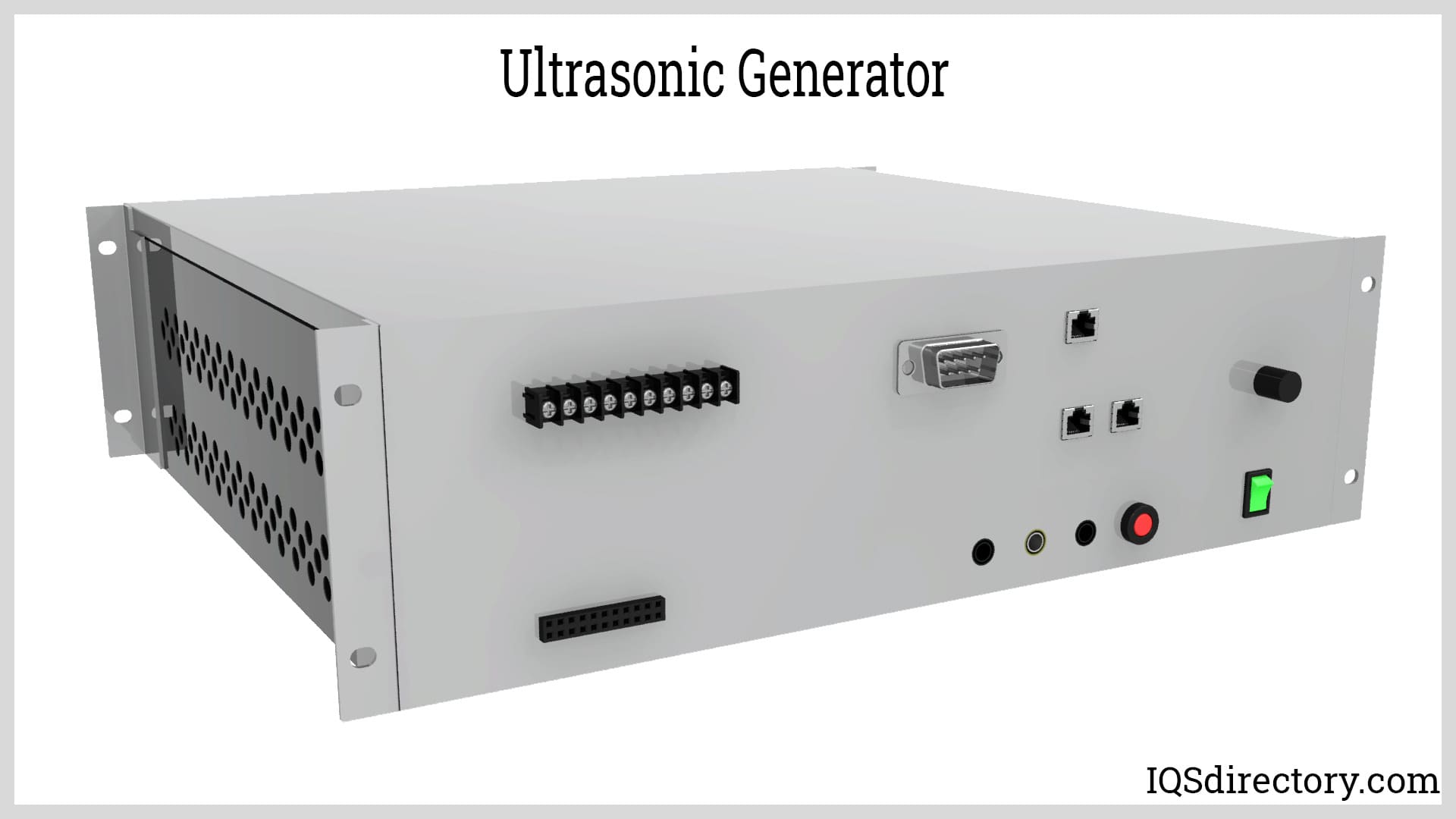

Ultrasonic Generators

An electronic ultrasonic generator is the cleaning machine’s power source. It collects the AC electrical energy from a power source, such as a wall outlet, and changes it into the electrical energy necessary to activate an ultrasonic transducer. The operation of the ultrasonic generator involves supplying electrical energy pulses to the transducer to produce mechanical waves in the cleaning fluid for vibratory ultrasonic washing.

Ultrasonic Tanks

These tanks house both the things to be cleaned and the ultrasonic bath's liquid. Tanks should be made of stainless steel, and the size of the things to be cleaned will determine their capacity. Using cavitation bubbles created by the ultrasonic sound waves, solutions in ultrasonic cleaning tanks clean parts and components. Ultrasonic cleaning tanks must tolerate the cleaning action and vibrations produced by the transducers, and they must be built to meet various cleaning needs.

Advantages of Ultrasonic Cleaners

The following are the benefits of using an ultrasonic cleaner:

- Compared to other procedures, it is more effective at eliminating impurities, takes less time, and extends the life of the cleansed components. The completed surface reduces wear and friction, which lowers the cost of materials by reducing the amount of rejected parts.

- Higher energy levels enable it to penetrate nooks, crannies, and clear surface soils.

- Solvent costs are significantly decreased.

- This procedure is eco-friendly because it minimizes emissions and biodegradable trash.

- Water is the greatest detergent because it is environmentally safe, non-flammable, and toxic-free. Furthermore, compared to other organic solvents, the cavitation energy in a water-based solution is stronger.

Disadvantages of Ultrasonic Cleaners

The following are the drawbacks of an ultrasonic cleaner:

- The efficiency of the transducer influences the effectiveness obtained throughout the cleaning cycle and duration. Therefore, buying an ultrasonic cleaner from a reputable brand is advised.

- Other elements like heat, power, frequency, detergent type, and time impact the cleaning process.

- It is made up of electronic components vulnerable to high temperatures damage. As a result, the ideal temperature levels are kept as the ultrasonic cleaner manufacturer advises.

- Professionals must maintain the right temperature. This is because when a liquid's boiling point is reached, it will do so in a region of negative pressure created by sound waves. This lessens or completely prevents cavitation.

- Ultrasonic cleaning calls for a knowledgeable operator. Furthermore, one must read the user manual before beginning the cleaning process.

Choosing the Proper Ultrasonic Cleaning Machine Supplier

To make sure you have the most positive outcome when purchasing ultrasonic cleaning machines from an ultrasonic cleaning machine supplier, it is important to compare at least 4 suppliers using our ultrasonic cleaning machine directory. Each ultrasonic cleaning machine supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each ultrasonic cleaning machine business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple ultrasonic cleaning machine businesses with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services