Ultrasonic cleaning equipment uses transducers to generate powerful ultrasonic sound frequencies that cause tiny bursting bubbles in a liquid cleaning solution. When products are submerged in an agitated fluid, the bubbles provide a scouring action that reaches crevices and concealed areas. Adjusting the sound wave frequencies can vary the cavitation or the development and collapse of the bubbles. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Cleaning Equipment Manufacturers

Design of Ultrasonic Cleaning Equipment

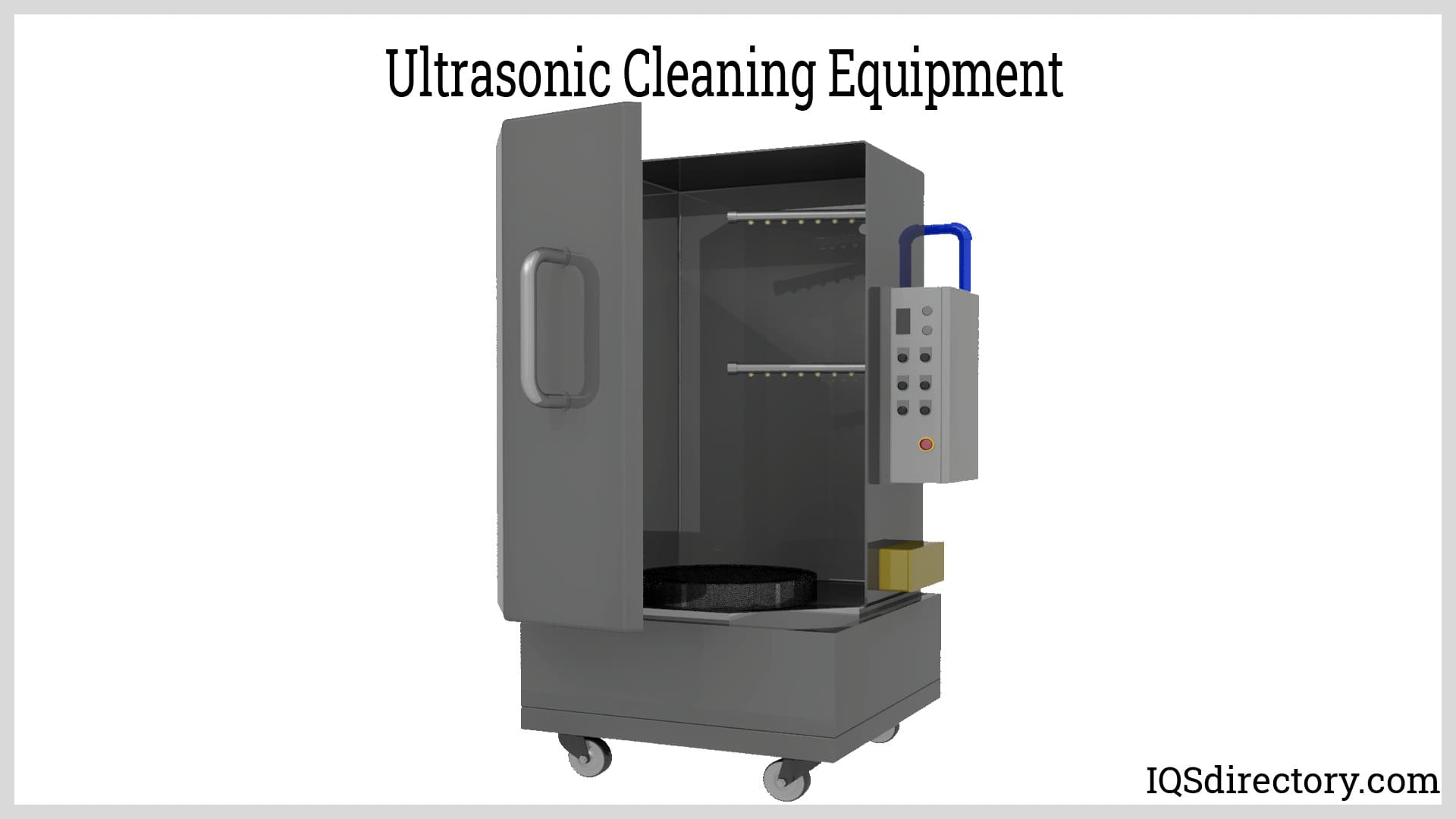

Every piece of ultrasonic cleaning equipment has a transducer, a generator, and an immersion tank. Tanks can be small and mobile or large industrial tanks. Equipment that needs cleaning is immersed in the ultrasound-conductive fluid-filled tank.

How Ultrasonic Cleaning Equipment Works

- Cavitation is a physical occurrence that occurs in fluctuating, brief-period oscillating high-pressure zones. A wave is transmitted into the cleaning solution at a high frequency to produce varying pressure. Small bubbles or voids are created and instantly implode. Shockwaves from the implosions are brief but extremely strong. Invisible to the human eye, these shockwaves scrape away dirt from the part cleaned at the microscopic level.

- Cavitation is a seriously harmful phenomenon in other industrial machinery that can quickly corrode metal components like pump impellers and casings. Because of this, cleaner process parameters utilized in cleaning applications must be properly managed. Strong cavitation could harm the component being cleaned.

- The generator, transducer, and tank are the three basic components of an ultrasonic cleaner. The ultrasonic generator is the primary element in charge of obtaining utility electricity and transforming it into an electrical signal. The target process frequency is oscillated by this electrical signal. Typically, the common utility power frequency is 50 or 60 Hz. The generator output frequency ranges from 20 kHz to 80 kHz and is hundreds of times higher.

Applications of Ultrasonic Cleaning Equipment

Ultrasonic cleaning equipment is utilized in many commercial and industrial applications because it can simultaneously clean multiple parts. For example, people clean jewelry or firearms. Automotive manufacturers use ultrasonic cleaning equipment for critical cleaning and pre-and post-production cleaning.

Types of Ultrasonic Cleaning Equipment

Medical and dental ultrasonic cleaning Equipment: Ultrasonic cleaners can decontaminate medical instruments interacting with blood, tissue, and protein-based pollutants. Surgical instruments, implants, fasteners for surgical screws and fasteners, needles, blades, cutters, and lab ware are often sterilized with ultrasonic cleaning equipment.

Gun cleaners with ultrasound: Brushes and polishers cannot get into the numerous hollow spaces, caverns, and crevices that make up a gun's assembly. Additionally, conventional gun cleaning employs solvents that are typically bad for the environment. Ultrasonic gun cleaners can reach all surfaces as long as they are adequately wetted with the cleaning solution.

Ultrasonic cleaner for electronics: Ultrasonic cleaners are used to clean circuit boards and other electronics because of their meticulous cleaning capabilities. Debris present in semiconductors and electronics can be removed using ultrasonic cleaners. Small metal chips and burrs can be removed while preserving the intricate features of the electrical components. This guarantees electronic products will operate dependably.

Choosing the Right Ultrasonic Cleaning Equipment Company

To make sure you have the most productive outcome when purchasing ultrasonic cleaning equipment from an ultrasonic cleaning equipment company, it is important to compare at least 5 to 6 companies using our ultrasonic cleaning equipment directory. Each ultrasonic cleaning equipment company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each ultrasonic cleaning equipment company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple ultrasonic cleaning equipment companies with the same message.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services