“Ultrasonics” refers to the study and use of mechanical vibrations exceeding the range of human hearing. Ultrasonic parts washers operate by using ultrasonic frequencies to cause regulated cavitation in tanks of cleaning fluid. The cavitation bubbles grow in these tanks and abruptly implode, releasing a great amount of energy against the surfaces of submerged items. High frequencies produce smaller but more numerous cavitations, while low frequencies produce larger cavitations. This implosion is the core of the ultrasonic process. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Parts Washer Manufacturers

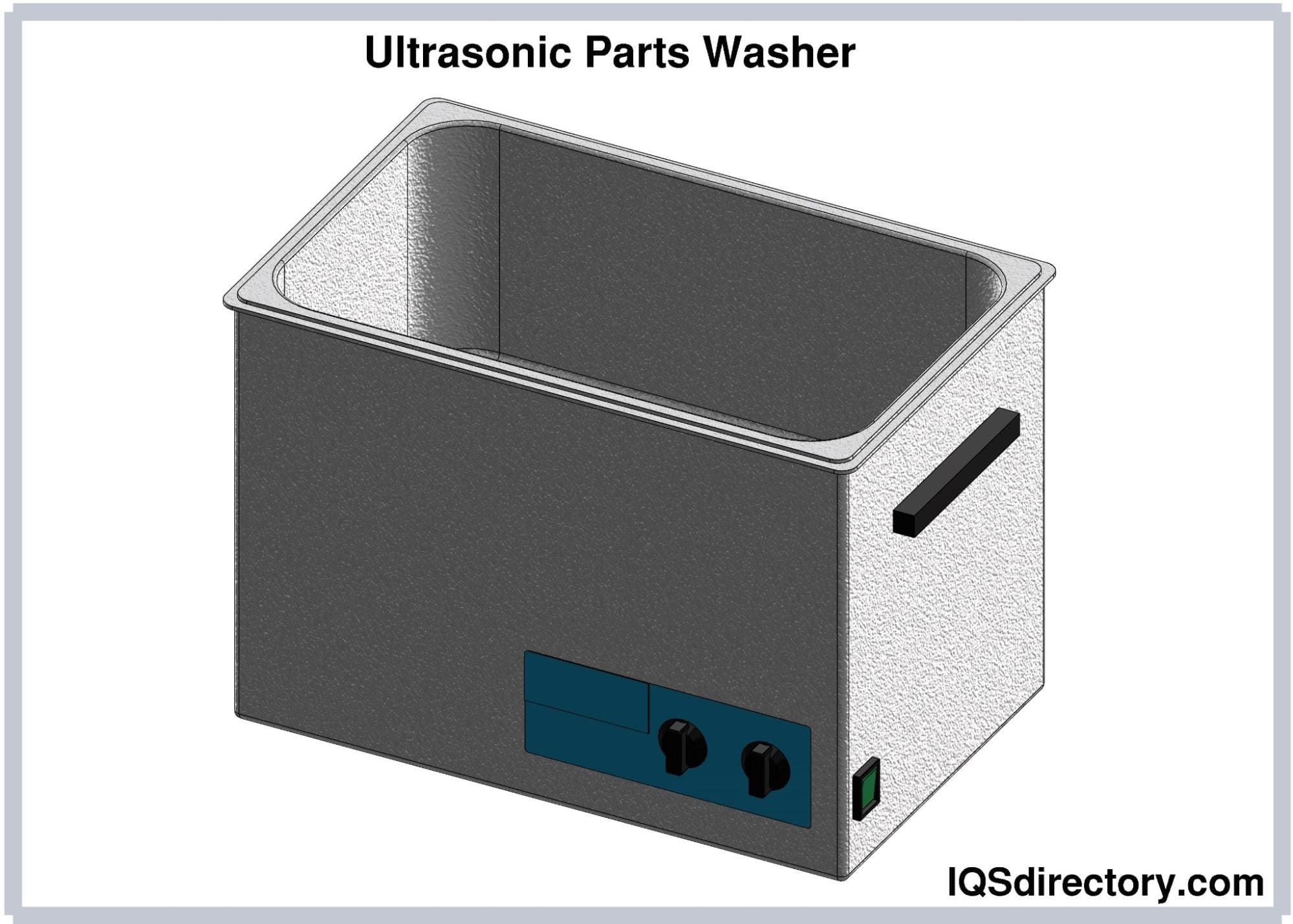

Parts of an Ultrasonic Parts Washer

To help remove stubborn dirt from parts, ultrasonic cleaning uses ultrasonic energy in an immersion cleaning tank. There are three essential parts to an ultrasonic system:

- A tank to store the cleaning agent and the unclean components

- An ultrasonic generator

- Transducers that transform the electrical data from an ultrasonic source into mechanical energy

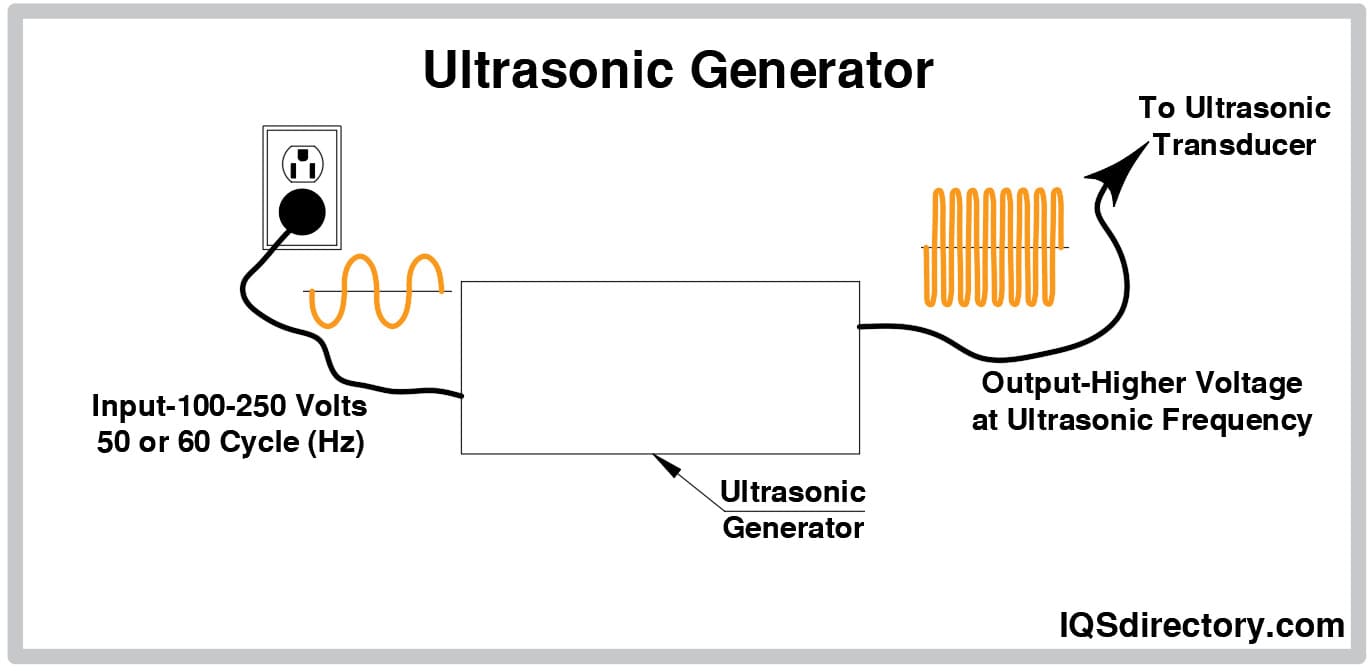

Ultrasonic Generators

The ultrasonic generator transforms AC electrical energy from the power line to produce electrical energy alternating at the desired ultrasonic frequency. The ultrasonic generator may also include intricate circuitry that automatically adjusts its output to the ultrasonic transducer's best working frequency.

Ultrasonic Transducers

An ultrasonic transducer transforms electrical energy into mechanical motion-sound. As a result, the cleaning tank receives sound energy from the transducer.

Ultrasonic Cleaning Working Principle

An ultrasonic degreaser operates by creating controlled cavitation in the cleaning fluid. Cavitation describes the formation of tiny spaces or "bubbles" in a fluid when the transducers generate enough ultrasonic energy. When the cavitation bubbles suddenly burst after forming slowly, they unleash a great amount of energy onto the surfaces of any items submerged in the tank, vigorously "scrubbing" away any soils.

To remove dust, grime, grease, and scale, ultrasonic parts washing equipment uses ultrasonic waves in a mixture of water and chemical cleaners (or the chemicals can be omitted). The transducer, which generates the ultrasonic waves that clean the parts, is one of the most crucial components of an ultrasonic cleaner.

The most common type of transducer is the piezoelectric transducer. However, they are made of fragile materials, which enables "hot spots" that cause the transducer to degrade and become stressed at high temperatures. Other manufacturers employ magnetostrictive transducers, which have more vital parts for a longer life cycle and the elimination of "hot spots," resulting in more uniform cleaning.

Types of Ultrasonic Parts Washers

Custom Ultrasonic Parts Washer

Specialized ultrasonic parts washers are designed to function in a particular application. Industry-specific systems, such as automated indexing, semi-automated, turbine engine fuel nozzle cleaning, etc., can be redesigned and set for specialized cleaning applications.

Inline Ultrasonic Parts Washer

A facility will benefit from automation thanks to inline ultrasonic parts washers. Inline cleaning systems can be mounted on flat wire mesh belts or overhead conveyors. Since less direct labor is involved, parts can move quickly through the entire application. This provides essential cleaning for items of all sizes.

Large Ultrasonic Parts Washer

A variety of tank sizes are available to manage hefty workloads, long work cycles, and harsh chemicals. In addition, industries with enormous cleaning capacity requirements can benefit from the great performance and dependability of large tanks. These ultrasonic cleaning systems use high-powered ultrasonics and stainless steel tanks to provide dependable, consistent performance.

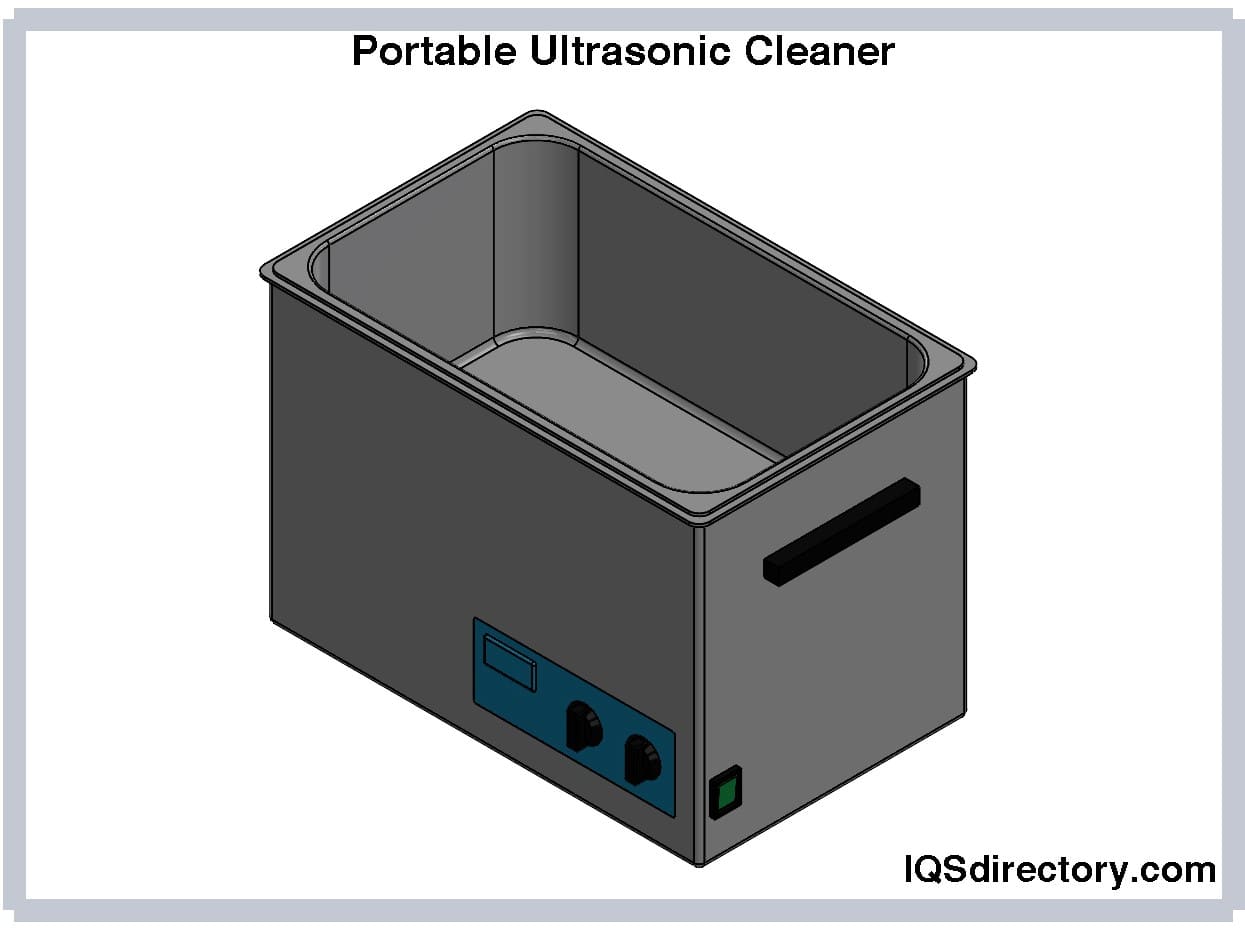

Portable Ultrasonic Parts Washer

Portable units allow flexibility in the location where the parts are washed. These machines can wash pieces of all shapes and complexities and are perfect for small to medium-sized parts.

Benefits of Ultrasonic Parts Washers

Ultrasonic cleaners address the shortcomings of oscillation and spray-washing techniques. Some of their benefits include the following:

- Detailed Cleaning – Ultrasonic cleaning devices can reach microscopic details on a surface and clean inside holes as thin as human hairs. They can even clean the insides of parts that cannot be cleaned with oscillation or spray techniques, such as tubing interiors, closed chambers, channels of injection molds, carburetors, intricate solenoid valves, and other parts.

- Tough on Pollution – Ultrasonic cleaners can eliminate even the most difficult pollutants with proper cleaning solutions.

- Simple to Maintain – In the past, oscillation and spray washing systems required more upkeep than ultrasonic cleaners.

- Consistent Cleaning Outcomes – An ultrasonic parts washer’s performance is not significantly impacted by variations in contamination because the surface of the parts is being washed microscopically.

- Time-Saving – Ultrasonic cleaners produce up to 40,000 sound pulses per second, and each pulse cleans the surface of the part it touches. Ultrasonic cleaners can remove impurities more quickly and effectively than other cleansers because of this high-frequency wave action.

- Gentle Cleaning – Ultrasonic cleaners are the best choice for cleaning even the most delicate parts since they eliminate impurities without abrasion, rough scrubbing, or high-pressure sprays. For this reason, they are employed to clean microchips, computer components, plated parts, and priceless family artifacts.

- Versatile Contaminant Removal – Oil, grease, wax, shavings, dirt, dust, clay, sand, parting compound, soot, charcoal, and oxidation are just a few pollutants ultrasonic cleaners may remove from a part's surface, down to tiny particle size. Any other parts cleaning system in the same unit does not provide that degree of versatility.

- No Part Too Complex – Hidden passages, small gaps, crevices, fractures, and blind-drilled holes receive the same level of cleaning as visible surfaces without the expensive cost of hand-cleaning since the cleaning solution and high-frequency waves permeate all surfaces.

- Low Power Consumption – Ultrasonic cleaners use only one small motor to filter the solution, as opposed to other parts-cleaning systems requiring numerous motors to pump, spray, circulate, agitate, and catch the cleaning agent and its fumes. Transducers and effective electrical power are used to complete the remaining cleaning tasks while consuming the least amount of power possible.

Choosing the Proper Ultrasonic Parts Washer Manufacturer

To make sure you have the most beneficial outcome when purchasing ultrasonic parts washers from an ultrasonic parts washers manufacturer, it is important to compare at least 4 or 5 manufacturers using our ultrasonic parts washers directory of ultrasonic parts washers manufacturers. Each ultrasonic parts washers manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ultrasonic parts washers company's website using our patented website previewer to get an idea of what each company specializes in, and use our simple RFQ form to contact multiple ultrasonic parts washers companies with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services