An ultrasonic jewelry cleaner uses ultrasonic sound waves to clean jewelry. These machines use ultrasonic sound waves to remove difficult dirt, grease, oil, and other materials from jewelry pieces. Rings, necklaces, watch bands, and other jewelry items can be cleaned and sanitized using ultrasonic jewelry cleaners. Even the most difficult-to-reach jewelry cracks and crevices may be cleaned using these tools and the proper cleaning solution. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Jewelry Cleaner Manufacturers

People use aqueous and organic solvents in the ultrasonic jewelry cleaner when cleaning jewelry. Aqueous cleaners are exceptionally mild on jewelry because the solvent in the solution is water. An organic cleaning solvent has a chemical solvent that, depending on the chemical used, can be too harsh for jewelry. Surfactants, detergents, and ammonia are the best cleaning options for ultrasonic jewelry cleaning equipment.

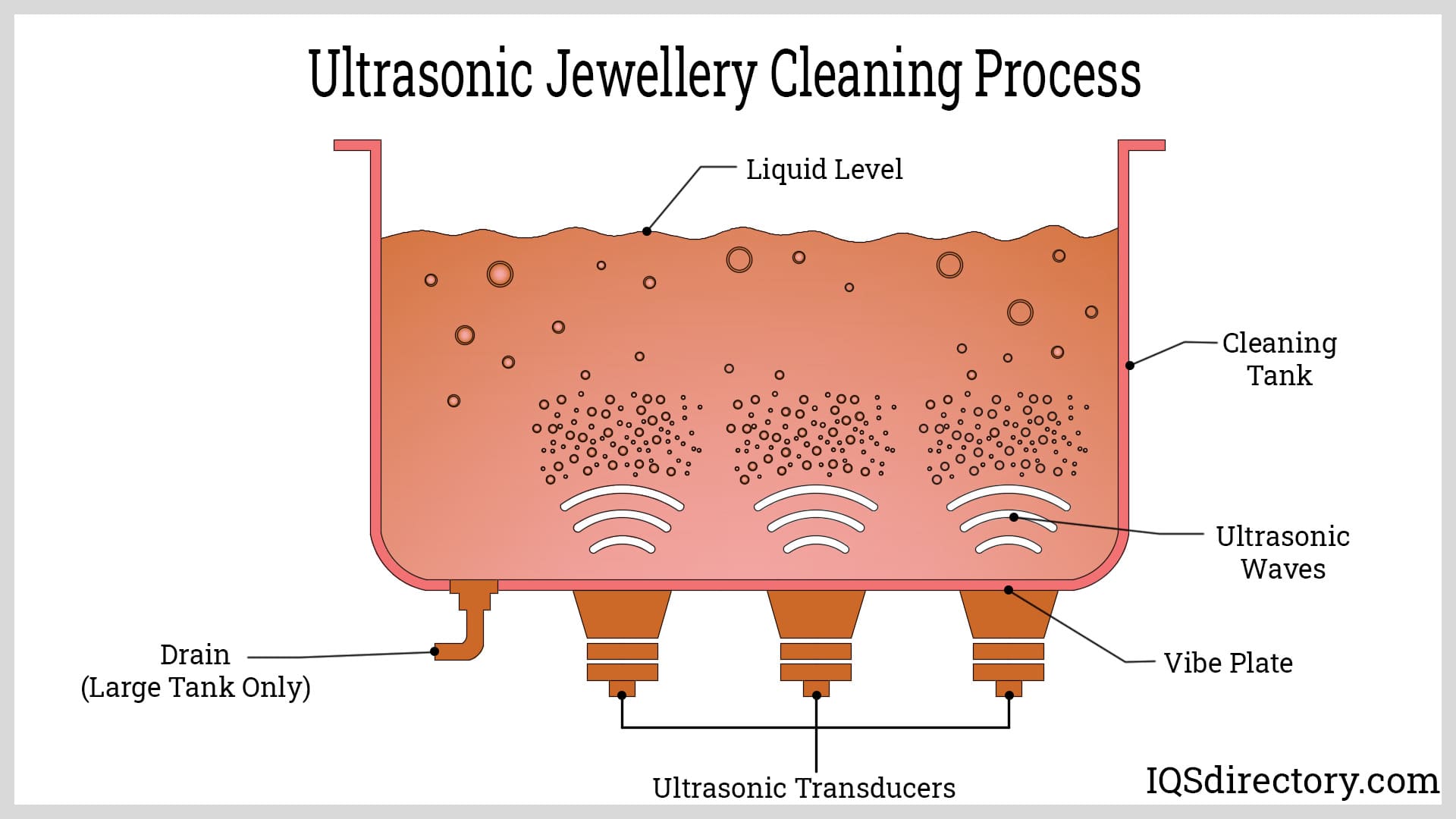

Ultrasonic jewelry cleaners consist of a power supply, an immersion tank, a generator, and a transducer. The transducer sends ultrasonic sound waves into the tank containing the jewelry-holding basket. The control panel contains options for choosing the temperature and time restriction. When cavitation takes place, the ultrasonic cleaning procedure starts.

Ultrasonic waves pass through the liquid, stretching and compressing the cleaning agent until the molecules can no longer be stretched. The liquid's disintegration and negative pressure creates many bubbles. These bubbles get bigger until equilibrium is attained, at which point they quickly compress.

The collapsing bubbles produce millions of small, strong microbursts that scrub every surface of the jewelry item clean. Some businesses have switched to biodegradable solvents that minimize the risk of ozone depletion and other environmental concerns. Safer, water-based alternatives replace some degreasing chemicals. In addition, several businesses are now reworking their cleaning equipment to ensure that the solvent is automatically recovered without a major waste stream.

Advantages of Ultrasonic Jewelry Cleaners

Ultrasonic jewelry cleaners are fast, easy to operate and produce consistent results. In addition, they leave jewelry sparkling. Although this method may be too abrasive for some jewels, ultrasonic jewelry cleaners are perfect for cleaning most metal jewelry, including gold, stainless steel, and silver. An ultrasonic jewelry cleaner can be beneficial for durable stones like diamonds, rubies, garnets, and sapphires, but it could dull or harm softer stones like emeralds, amber, opals, and pearls.

Choosing the Right Ultrasonic Jewelry Cleaner Manufacturer

To make sure you have the most productive outcome when purchasing ultrasonic jewelry cleaners from an ultrasonic jewelry cleaner manufacturer, it is important to compare at least 4 to 5 manufacturers using our ultrasonic jewelry cleaner directory. Each ultrasonic jewelry cleaner manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ultrasonic jewelry cleaner business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple ultrasonic jewelry cleaner businesses with the same form.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services