An ultrasonic washer is a washing machine that employs high-frequency vibrations to stir the water and remove stains. In addition, they employ the inherent strength of sound waves to eliminate bacteria, mildew, and other household dirt. But there are certain drawbacks to using ultrasonic equipment. Their biggest downside is that they can typically only be utilized for light loads. This is because the size of a machine that it can pump depends on the volume of water. This implies that using anything significant in an ultrasonic machine requires no more than half a full load. Read More…

Since 1972, Esma Inc. has been producing quality ultrasonic cleaners, as well as benchtop electropolishing equipment. Esma offers a unique and progressive approach to automating the ultrasonic cleaning process.

Since 1992 Telsonic Ultrasonics has been manufacturing ultrasonic cleaners such as compact cleaners and industrial tanks. As a specialist in ultrasonic technology, we offer innovative applications within the parts and optics industries and even chemical and pharmaceutical products. Our brand new facility houses cutting-edge technology where we strive to improve the quality of our products.

Great Lakes Finishing Equipment, Inc. is a full line supplier of aqueous and semi-aqueous ultrasonic cleaning equipment. Equipment includes benchtop cleaners, tank and generator series, immersible transducers, console systems and engineered systems. Our customers include defense, aerospace, medical, firearms and industrial.

Sonic Systems is a recognized leader in the design and manufacture of both ultrasonic cleaners as well as ultrasonic cleaning systems and components for a broad range of industries. We also offer aqueous cleaning equipment and systems.

More Ultrasonic Washing Machine Manufacturers

Using an Ultrasonic Cleaner

Numerous industries, such as those producing medical devices, automobiles, aircraft, dental work, electronics, jewelry, and weapons, frequently use ultrasonic cleaning equipment. Medical and surgical instruments, carburetors, weapons, window coverings, industrial machine parts, and electronic equipment are ideal for cleaning ultrasonic parts.

Depending on the material and contaminants, ultrasonic cleaning might take anywhere from 3 to 6 minutes to complete. Electronics and other fragile objects may require more time to clean. Most industrial parts cleaners use heat from 135 °F to 150 °F (57 °C to 65 °C) because higher heat helps release dirt and chemical bonds more quickly.

Note that using an ultrasonic bath cleaner to clean doesn't sterilize anything. Sterilization is often the next step in the procedure after ultrasonic cleaning in medical applications.

Ultrasonic Cleaning Machines Working Principle

The following fundamental parts make up an ultrasonic cleaning device, often known as an ultrasonic bath device or ultrasonic washer:

Ultrasonic Cleaning Tank – The articles to be cleaned are kept in the ultrasonic cleaning tank and ultrasonic bath fluid.

Ultrasonic generator – AC electrical energy is converted to an ultrasonic frequency by the ultrasonic generator.

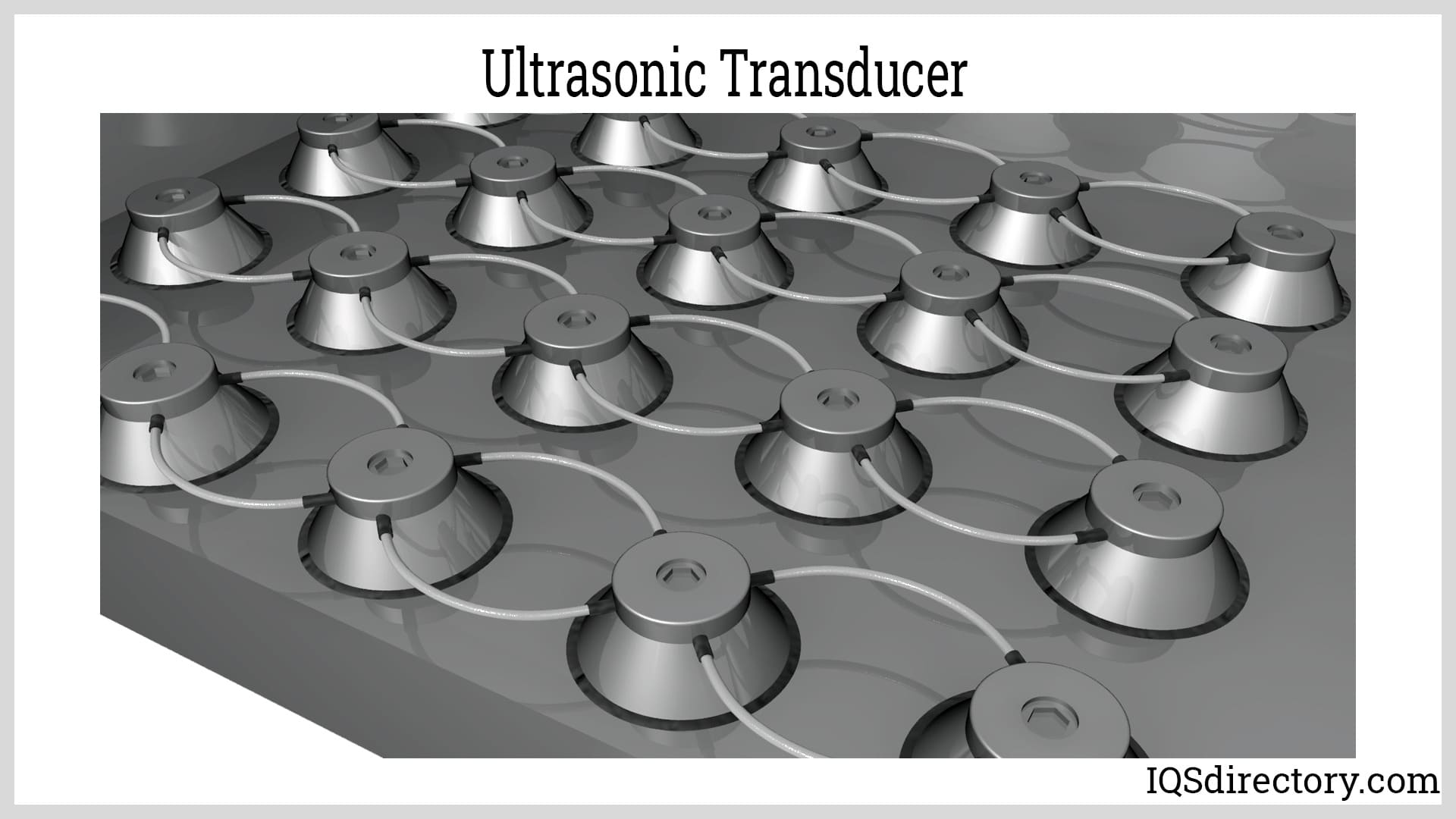

Ultrasonic transducer – The transducer transforms the electrical signal from ultrasonic into mechanical energy.

Ultrasonic Transducer

The essential element of an ultrasonic cleaning device is the ultrasonic transducer. The ultrasonic transducer, also known as an ultrasonic vibration generator, is a device that produces sound above the human hearing range, often beginning at 20 kHz. A backing, a radiating plate, and an active element make up an ultrasonic transducer. The active element in the majority of ultrasonic cleaners is a piezoelectric crystal.

Through the piezoelectric effect, which occurs when crystals receive electrical energy and change size and shape, the piezoelectric crystal transforms electrical energy into ultrasonic energy. The thick backing of an ultrasonic transducer absorbs the energy that radiates from the back of the piezoelectric crystal. An ultrasonic transducer's radiating plate functions as a diaphragm to transform ultrasonic energy into mechanical (pressure) waves in the fluid.

Ultrasonic Generator

An electronic ultrasonic generator is the machine’s power source. It changes AC electrical energy from a power source, such as a wall outlet, into the electrical energy necessary to activate an ultrasonic transducer. In other words, the transducer receives high-voltage electrical pulses from the ultrasonic generator. To create mechanical waves in the cleaning fluid for vibratory ultrasonic washing, the ultrasonic generator works by delivering electrical energy pulses to the transducer.

Ultrasonic Frequency

While 40 kHz is the most popular ultrasonic frequency for cleaning ultrasonic parts, some applications benefit from a lower or higher frequency. For example, a frequency of 20 kHz could be used for larger, more highly contaminated goods since it produces cleaner bubbles that are stronger and bigger but produce fewer bubbles per second. On the other hand, some incredibly tiny, sensitive things could need higher ultrasonic cleaning frequencies, up to 200 kHz. In general, a higher frequency allows for the cleaning of more intricate detail.

Advantages of Ultrasonic Cleaning

More and more businesses, from the dentist's office to the car shop, are employing ultrasonic cleaners to remove hazardous impurities and undesired residue from their equipment. Technological developments make ultrasonic cleaning safer, more effective, and more economical every year. Ultrasonic cleaners have several benefits compared to manual cleaning, machine washing, and other cleaning techniques.

Environment Impact

Until recently, heavy chemical cleaners were frequently used in numerous industries. Esters and chlorinated hydrocarbons, which can contaminate groundwater supplies, were often present in these cleaners. These chemicals also produced very hazardous vapors; thus, workers frequently needed masks to protect them from harmful fumes. An ultrasonic cleaner breaks up residue using water-soluble detergents rather than harsh chemicals.

Worker Safety

An ultrasonic cleaner helps workers avoid sharp objects that can be contaminated with biological agents and prevents them from breathing toxic chemical vapors. In the past, staff members manually cleaned surgical tools like scalpels and drill bits, which could cause a biohazard by puncturing the technician's skin. Instead, the worker only needs to put the instrument in the tank, add water and detergent, and turn on the ultrasonic cleaning.

Gentle Cleaning

Hand washing and strong chemicals can harm delicate items, including jewelry or fine instruments. Both a thorough cleaning and careful treatment are necessary for these items. An ultrasonic cleaner's cavitation effect enables the water and detergent solution to penetrate small cracks and remove waste while preserving the object's integrity.

Range of Application

Home hobbyists, state and federal law enforcement agencies, and ultrasonic cleaner users fall under this category. Home users use ultrasonic cleaners to clean their jewelry and collect coins to get rid of dirt, filth, and skin oils. With the help of an ultrasonic cleaner, auto repair businesses can remove old lubricants, metal burrs, and other debris that could prevent a car from operating at its peak performance. Finally, ultrasonic cleaners are used by law enforcement, sheriffs, and federal agents to clean their firearms, handcuffs, and other gear.

These machines come in various sizes, from compact desktop devices to bigger ones used to clean long-barreled weaponry like rifles and shotguns. Some cleaners employ specialist detergents to eliminate particular impurities, whereas other uses merely need tap water and several other ingredients.

High Efficiency

Users of ultrasonic cleaners have discovered that these devices are far more effective than hand-cleaning or other machine-based techniques. Three crucial resources are preserved when an ultrasonic cleaner is used:

Water: Compared to most hand-cleaning techniques or standard equipment-washing machines, ultrasonic cleaners use less water.

Electricity: More energy is saved by ultrasonic cleaners than by various equipment washers.

Time: Ultrasonic cleaners are significantly faster and more efficient than manual cleaning or washing machines.

Choosing the Right Ultrasonic Washing Machine Manufacturer

To make sure you have the most beneficial outcome when purchasing ultrasonic washing machines from an ultrasonic washing machine manufacturer, it is important to compare at least 4 to 5 manufacturers using our ultrasonic washing machine directory. Each ultrasonic washing machine manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ultrasonic washing machine company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple ultrasonic washing machine companies with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services